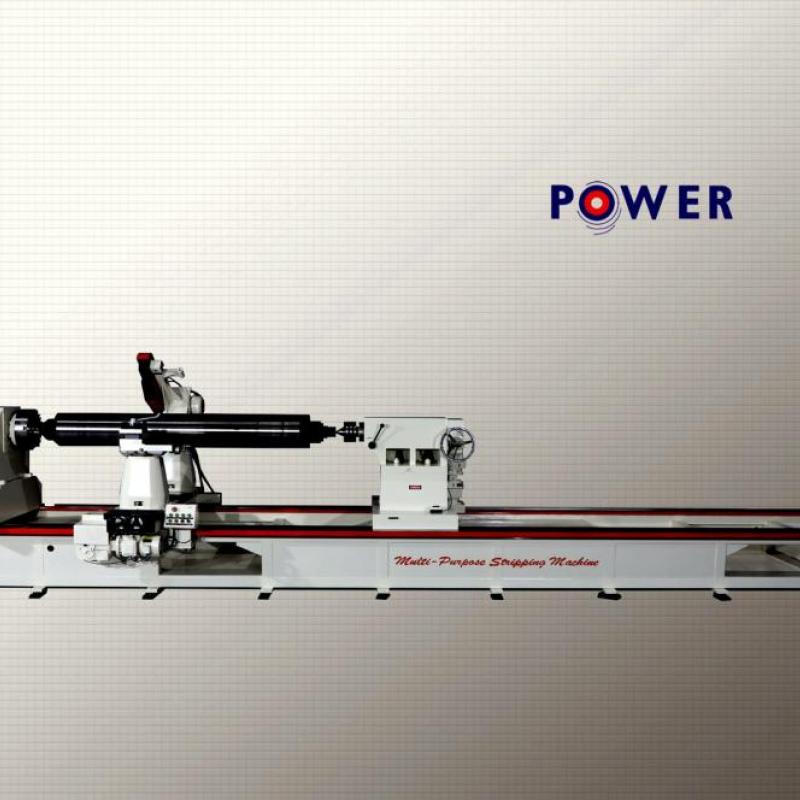

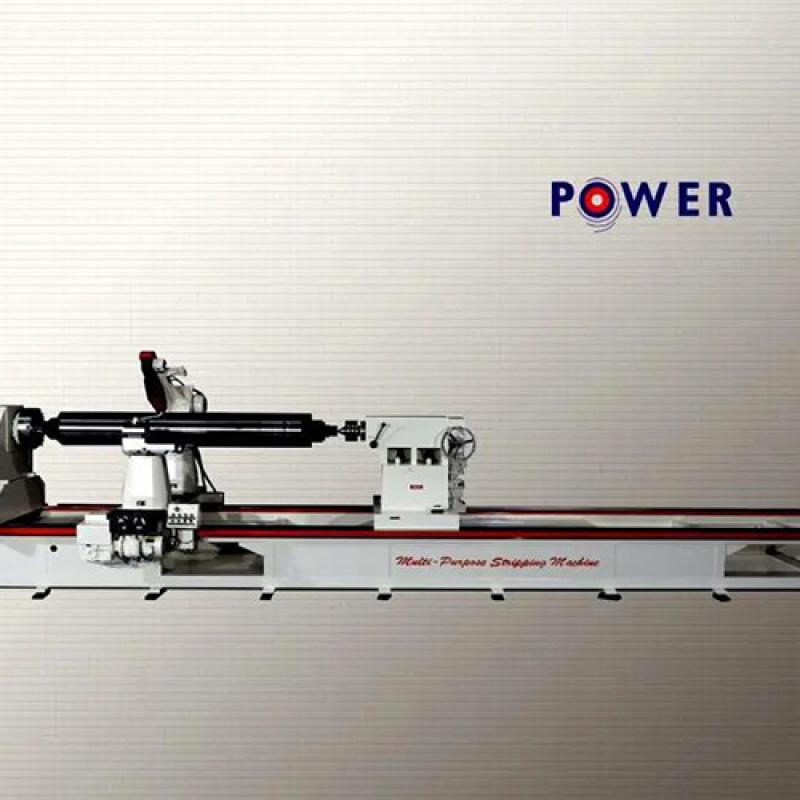

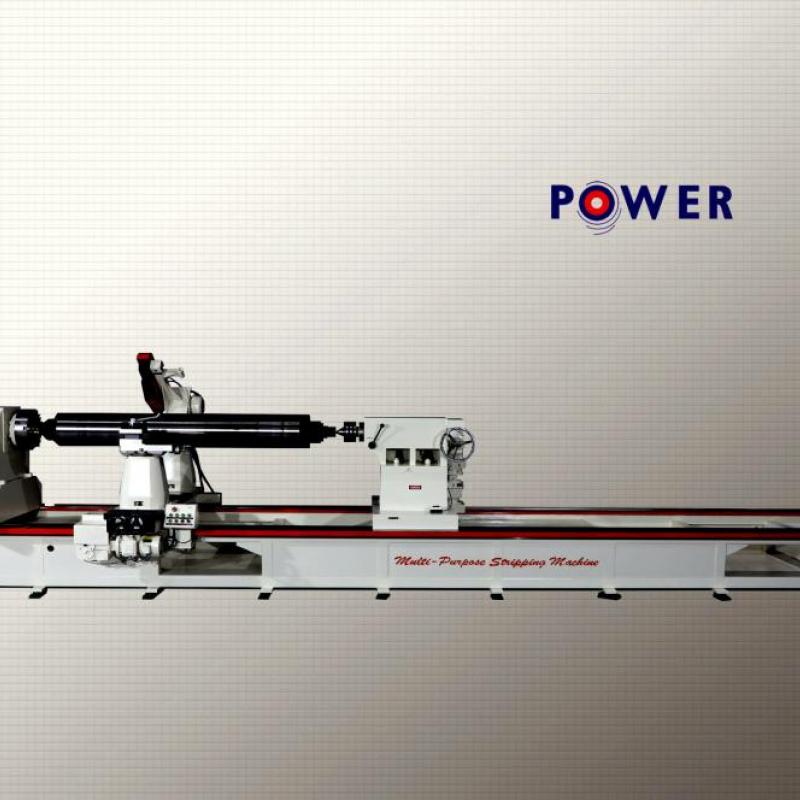

PCM Multi-Purpose Stripping Machine is eparticularly researched, evolved and designed for treating vintage Rubber Rollers. PCM Multi-cause Stripping Machine has the benefits that: Old rubber may be quick eliminated through a unique ring cutter, a curler middle could have a brand-new floor beneathneath the unique belt grinding mode. Adhesive brushing and drying are facilitated, bonding of rubber and the curler middle is ensured, which changed the conventional sand blasting process.

Contact Now

Product description1. the pcm-8040 model is appropriate for renewing commercial rubber rollers.2. eliminating antique rubber by using special ring cutter.Three. replacing the conventional sand-blasting and solvent washing technique by way of superior belt-grinding system.Four. flawlessly retaining the unique dynamic balance of the roller core.Five. giving more reliable assure for the bonding of the rubber and steel cores.6. saving expenses and labors with this stepped forward manufacturing machine.MODELSPECIFICATIONMAX. DIAMETERMAX.

Contact Now

PCM-6040 Muti-Purpose Rubber Roller Stripping / Renewing / Cleaning / Recycling MachinePCM Multi-Purpose Stripping Machine is specially researched, developed and designed for treating old rubber rollers. PCM Multi-Purpose Stripping Machine has the advantages that: Old rubber can be quickly removed by a special ring cutter, a roller core would have a brand-new surface under the special belt grinding mode. Adhesive brushing and drying are facilitated, bonding of rubber and the roller core is ensured, which replaced the traditional sand blasting process.

Contact Now

Product description1. the pcm-8040 model is suitable for renewing business rubber rollers.2. doing away with old rubber by special ring cutter.3. replacing the conventional sand-blasting and solvent washing technique by way of superior belt-grinding manner.Four. perfectly maintaining the unique dynamic stability of the roller middle.Five. giving extra dependable guarantee for the bonding of the rubber and metal cores.6. saving charges and labors with this progressed manufacturing device.MODELSPECIFICATIONMAX. DIAMETERMAX.

Contact Now

Product descriptionPCM Multi-Purpose Stripping Machine is mainly researched, advanced and designed for treating antique Rubber Rollers. PCM Multi-motive Stripping Machine has the benefits that: Old rubber may be fast eliminated with the aid of using a unique ring cutter, a curler middle might have a brand-new floor beneathneath the unique belt grinding mode. Adhesive brushing and drying are facilitated, bonding of rubber and the curler middle is ensured, which changed the conventional sand blasting process.

Contact Now

PCM-6040 Muti-Purpose Rubber Roller Stripping / Renewing / Cleaning / Recycling MachineProduct description1. The PCM-6040 model is suitable for renewing printing rollers, general industrial rollers and small industrial rubber rollers.2. Removing old rubber by special ring cutter.3. Replacing the traditional sand-blasting and solvent washing process by advanced belt-grinding process.4.

Contact Now

Product description1. The PCM-1660 model is suitable for renewing Industrial Rubber Rollers.2. Removing old rubber by special ring cutter.3. Replacing the traditional sand-blasting and solvent washing process by advanced belt-grinding process.4. Perfectly keeping the original dynamic balance of the roller core.5. Giving more reliable guarantee for the bonding of the rubber and steel cores.6. Saving costs and labors with this improved production system.MODELSPECIFICATIONMAX. DIAMETERMAX.

Contact Now

Product description1. The PCM-4030 model is suitable for renewing printing rollers, general industrial rollers and small Industrial Rubber Rollers.2. Removing old rubber by special ring cutter.3. Replacing the traditional sand-blasting and solvent washing process by advanced belt-grinding process.4. Perfectly keeping the original dynamic balance of the roller core.5. Giving more reliable guarantee for the bonding of the rubber and steel cores.6. Saving costs and labors with this improved production system.MODELSPECIFICATIONMAX. DIAMETERMAX.

Contact Now

Product description1. The PCM-1250 version is appropriate for renewing Industrial Rubber Rollers.2. Removing vintage rubber through unique ring cutter.3. Replacing the conventional sand-blasting and solvent washing method through superior belt-grinding method.4. Perfectly maintaining the unique dynamic stability of the curler core.5. Giving extra dependable assure for the bonding of the rubber and metallic cores.6. Saving prices and labors with this stepped forward manufacturing system. MODELSPECIFICATIONMAX. DIAMETERMAX.

Contact Now

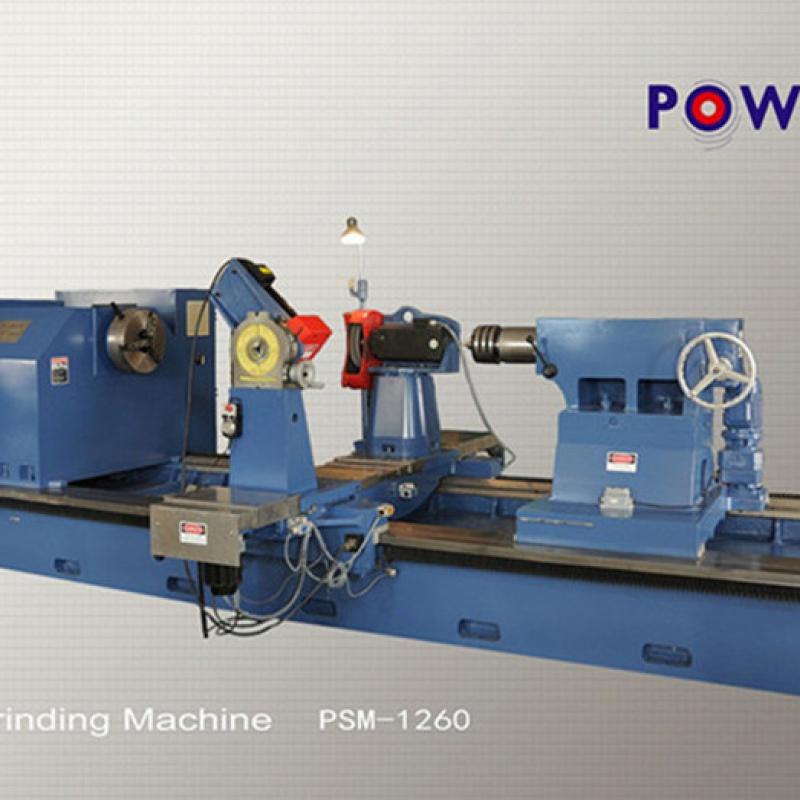

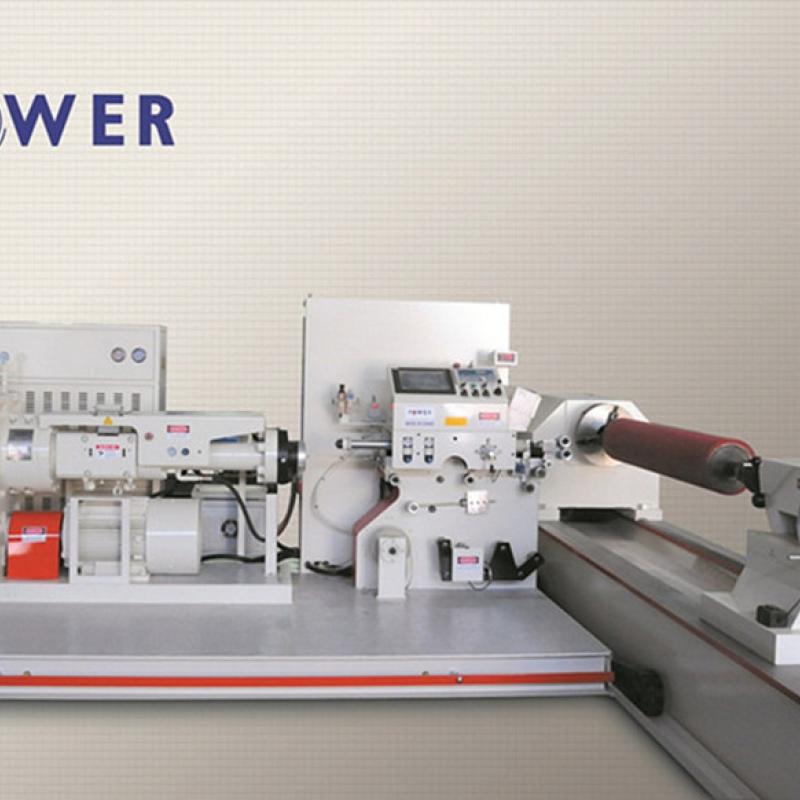

PSM-8040 General Rubber Roller Surface Grinding MachinePSM collection rubber curler grinding gadget is mainly designed and synthetic to replace the beyond roller processing approach by using way of steel production device. installation grinding head on the engine lathe is the past technique to fabricate curler, which the first-rate of curler is difficult to gain the requirement of the prevailing full-size. the primary purpose lies within the form of lathe.

Contact Now

Product description1. The PCM-8040 model is suitable for renewing Industrial Rubber Rollers.2. Removing old rubber by special ring cutter.3. Replacing the traditional sand-blasting and solvent washing process by advanced belt-grinding process.4. Perfectly keeping the original dynamic balance of the roller core.5. Giving more reliable guarantee for the bonding of the rubber and steel cores.6. Saving costs and labors with this improved production system.MODELSPECIFICATIONMAX. DIAMETERMAX.

Contact Now

PSM collection rubber roller grinding system is especially designed and artificial to replace the past curler processing method through the use of way of steel manufacturing device. set up grinding head on the engine lathe is the beyond approach to fabricate curler, which the great of roller is difficult to benefit the requirement of the prevailing giant. the number one purpose lies within the form of lathe. ultimately, it isn't always the grinding device; the transferring areas of the massive and medium carriage desk are huge than that of grinding tool.

Contact Now

Product description1. the pcm-8040 model is suitable for renewing industrial rubber rollers.2. putting off antique rubber by way of special ring cutter.Three. replacing the conventional sand-blasting and solvent washing procedure by advanced belt-grinding process.4. flawlessly keeping the original dynamic balance of the roller middle.5. giving more dependable assure for the bonding of the rubber and metallic cores.6. saving fees and labors with this advanced manufacturing gadget.MODELSPECIFICATIONMAX. DIAMETERMAX.

Contact Now

Product description1. The PCM-1250 model is suitable for renewing Industrial Rubber Rollers.2. Removing old rubber by special ring cutter.3. Replacing the traditional sand-blasting and solvent washing process by advanced belt-grinding process.4. Perfectly keeping the original dynamic balance of the roller core.5. Giving more reliable guarantee for the bonding of the rubber and steel cores.6. Saving costs and labors with this improved production system. MODELSPECIFICATIONMAX. DIAMETERMAX.

Contact Now

Product description1. The PCM-4030 model is suitable for renewing printing rollers, general industrial rollers and small Industrial Rubber Rollers.2. Removing old rubber by special ring cutter.3. Replacing the traditional sand-blasting and solvent washing process by advanced belt-grinding process.4. Perfectly keeping the original dynamic balance of the roller core.5. Giving more reliable guarantee for the bonding of the rubber and steel cores.6. Saving costs and labors with this improved production system.MODELSPECIFICATIONMAX. DIAMETERMAX.

Contact Now

Product description1. The PCM-4030 model is suitable for renewing printing rollers, general industrial rollers and small Industrial Rubber Rollers.2. Removing old rubber by special ring cutter.3. Replacing the traditional sand-blasting and solvent washing process by advanced belt-grinding process.4. Perfectly keeping the original dynamic balance of the roller core.5. Giving more reliable guarantee for the bonding of the rubber and steel cores.6. Saving costs and labors with this improved production system.MODELSPECIFICATIONMAX. DIAMETERMAX.

Contact Now

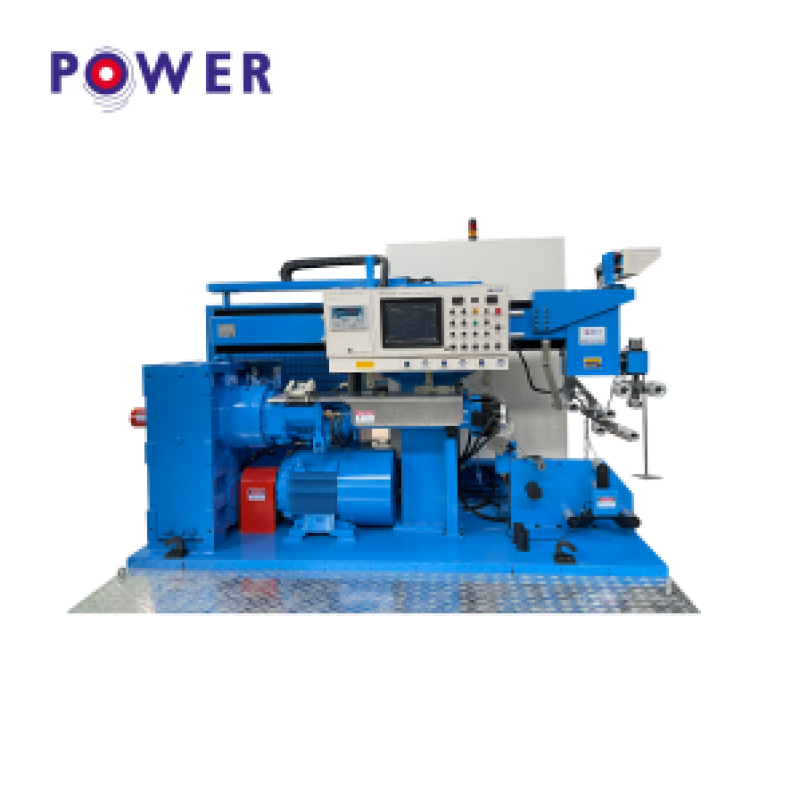

The Hydraulic rubber cutting machine The hydraulic rubber reducing system especially has the cutting glue knife, the device frame, the paintings oil cylinder, the bottom, the auxiliary work table and the hydraulic machine, the electric system and so forth component composes, the cutting glue knife base is ready with the nylon or the gentle lead backing plate, protects the slicing knife the blade.uncooked gum, with artificial glue inside the slicing knife below, and then press the begin button, then the cutting knife in the piston rod driven via the slide alongside the rack down the rubber

Contact Now

Factory Rubber Roller Grinding Machine For Textile The feature of PSM series factory rubber roller grinding machine for textile 1 Standard equipment of PSM series includes a a full flood recirculating coolant system b motorized tailstock c variable speed traverse and spindle drives d front and rear independently.The feature of PSM series factory rubber roller grinding machine for textile1. Standard equipment of PSM series includes:a. a full flood recirculating coolant systemb. motorized tailstockc. variable speed traverse and spindle drivesd.

Contact Now

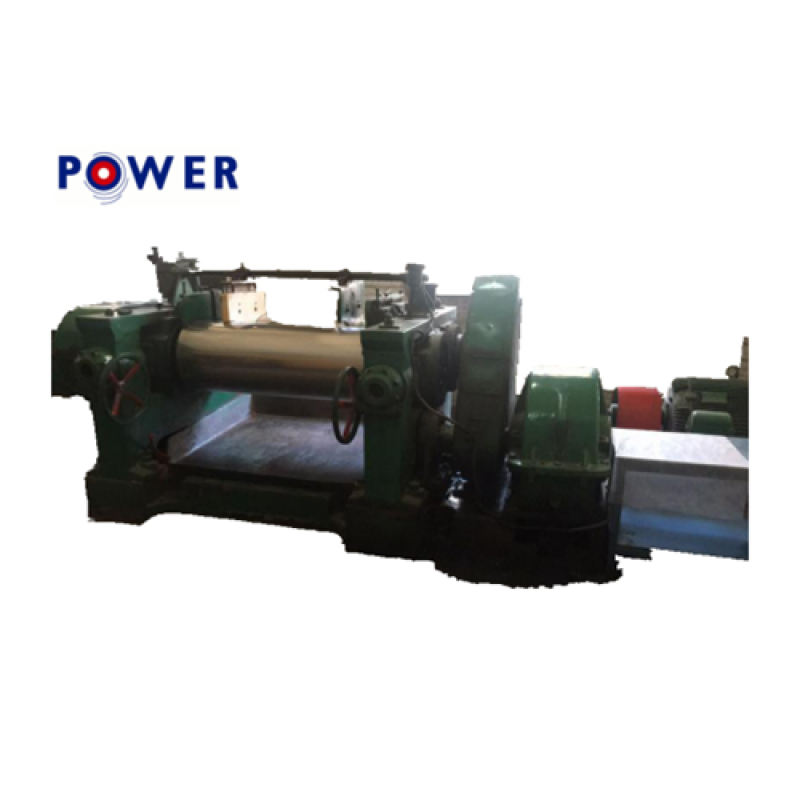

Used Open Rubber Mixing Mill 18" Two Roll / Second-hand Open Rubber Mixing Machine / Used Open Rubber Mixer Mill / Used Open Rubber Mixing MillUsed for rubber mixing and feeding for the next proocess. Second hand used machine with good condition.Product description18" Second-hand Used Rubber Open Mixing MillAbout usJinan Power Rubber Roller Equipment Co., Ltd is a modern private enterprise embodying scientific research and production.

Contact Now

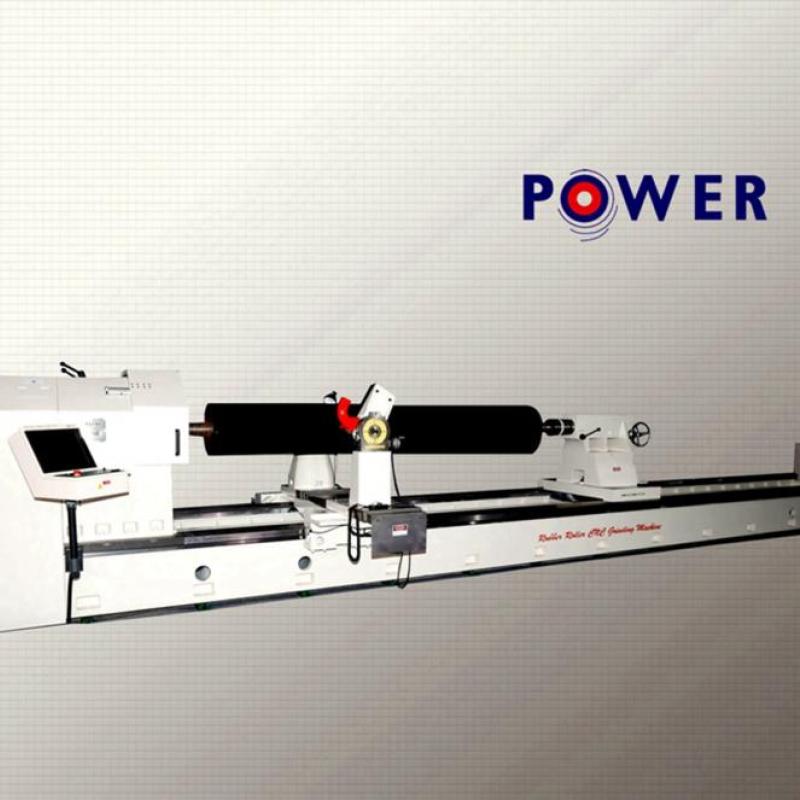

The feature of PSM series Jinan Rubber Roller CNC Roll Grinding Machine1. Standard equipment of PSM series includes: a. a full flood recirculating coolant system b. motorized tailstock c. variable speed traverse and spindle drives d. front and rear independently operated carriage tables e. a direct drive grinding head mounted on the rear2. Specially designed to replace the tradtional roller grinding process method.3.

Contact Now

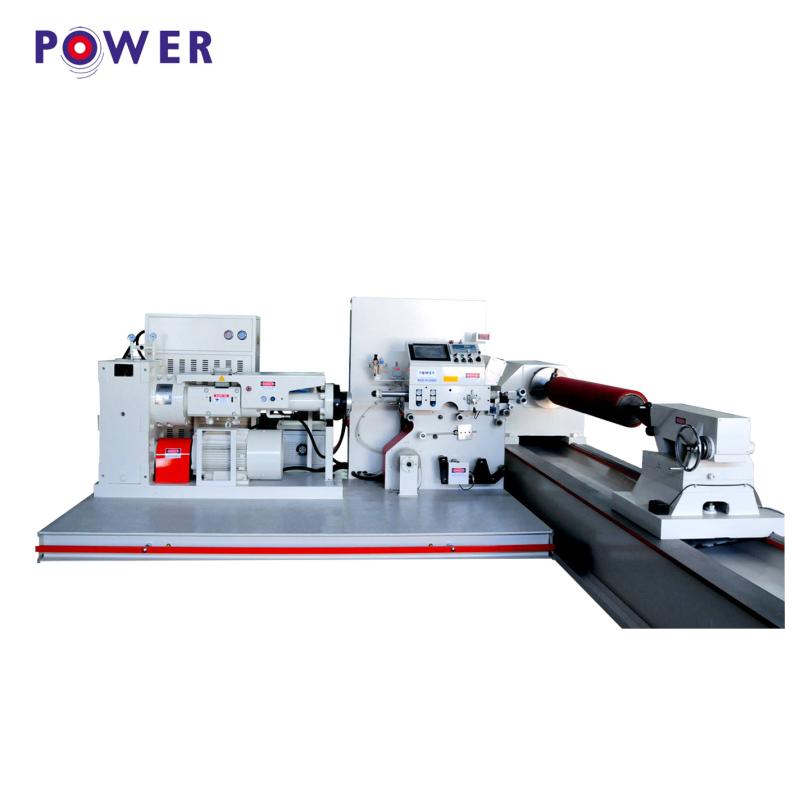

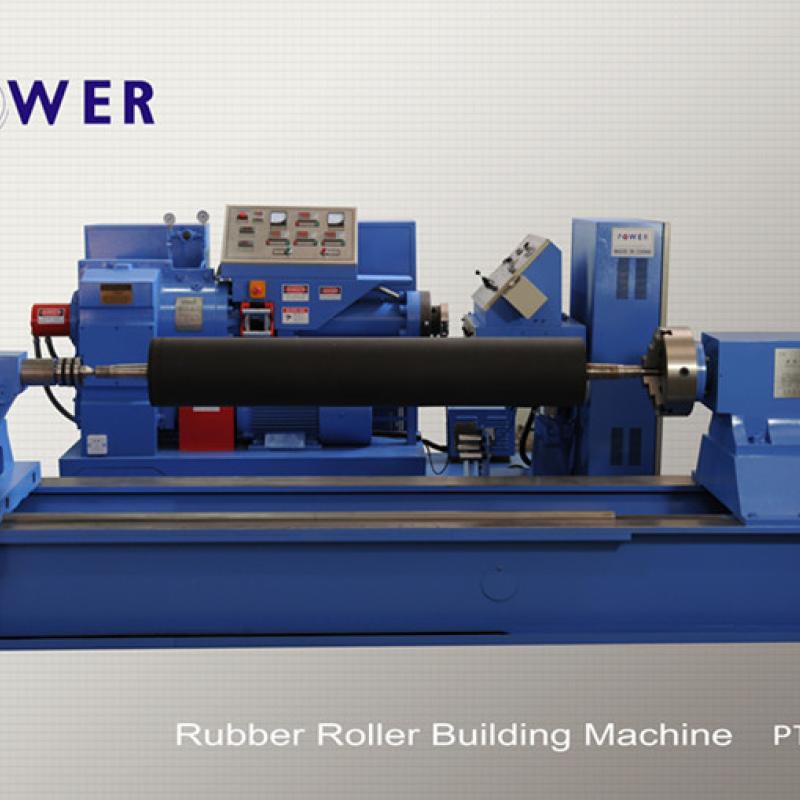

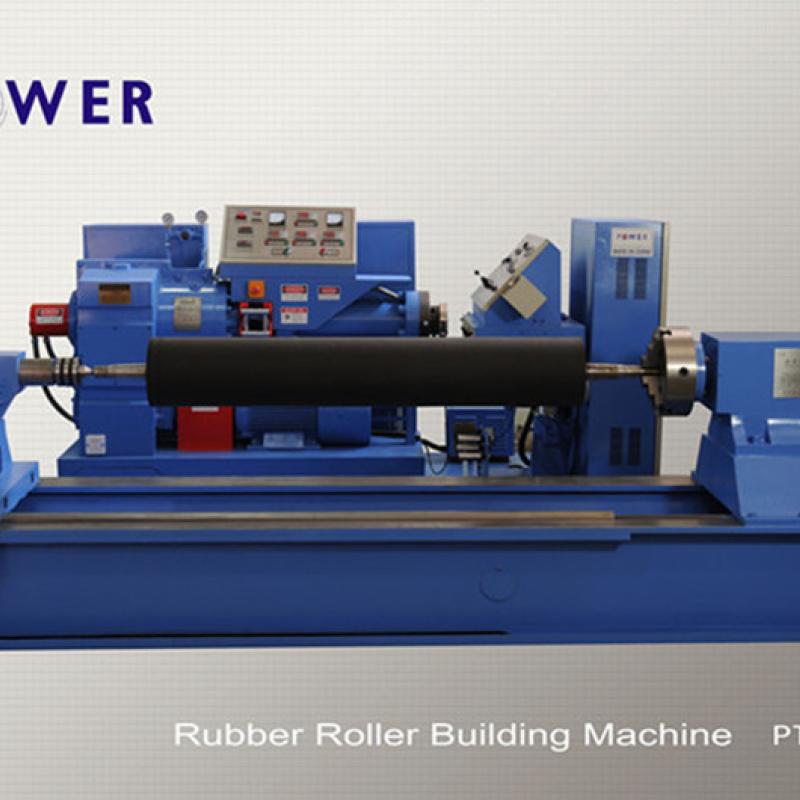

Product description1.Rubber roller building machine PTM-1080 model is suitable for processing industrial rolls such as steel mill rolls, textile rolls and dyeing rolls.2. Our rubber roller building machine equipped with E300CS power extruder and a complete industrial cooling system.3. The rubber roller building machine is applicable to rubber compounding with all hardness range 15-100A.4. The covering machine is easy Installation with our professional technical support.5.

Contact Now

Product description1.Rubber roller building machine PTM-1080 model is suitable for processing industrial rolls such as steel mill rolls, textile rolls and dyeing rolls.2. Our rubber roller building machine equipped with E300CS power extruder and a complete industrial cooling system.3. The rubber roller building machine is applicable to rubber compounding with all hardness range 15-100A.4. The covering machine is easy Installation with our professional technical support.5.

Contact Now

Due to the all-round of the system function, factory customized rubber roller groover can make almost all the profile of rollers. For instance, parabolic crowning and concave, cosine crowning and concave, circular, cone, coarse pitch, herringbone, diamond, straight groove, horizontal groove and other formations in the appended drawing.1.

Contact Now

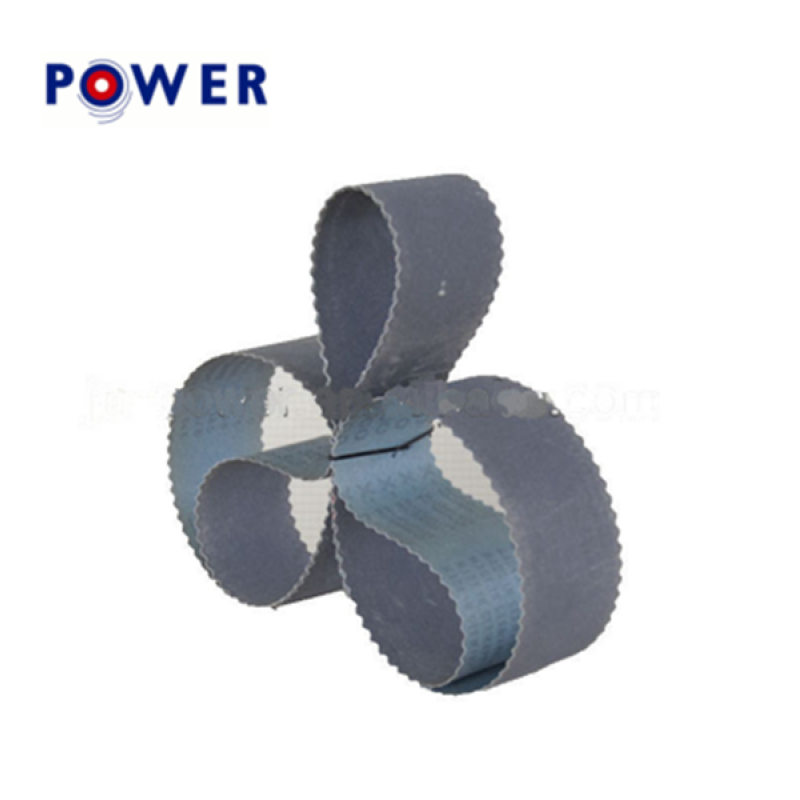

Product descriptionCharacteristic:1. can be used for water throwing and dry throwing;2. rubber belt polishing and roll core dehairing belt;3. there are multiple types, size and stylePackaging & ShippingAutomatic Rubber Roller Coating Machine Packing details:1. Outside package: Standard export wooden cases2. Inner package: Stretch filmShipping detail:Within 2-4 weeks

Contact Now